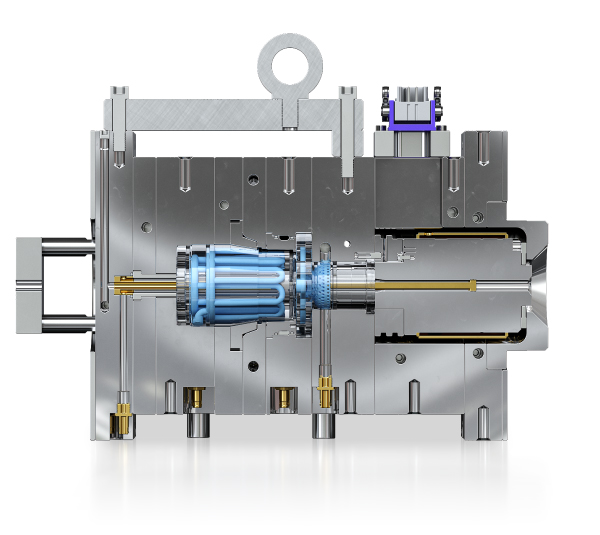

Optimised cooling in every mould

Traditional cooling channels are drilled in machine operations following straight lines, which can result in hot spots and issues with non-uniform polymer cooling and shrinkage. Historically, to resolve these issues, toolmakers employ a range of milling techniques from inserts to splitting the mould into segments. These processes are not only costly but have limited positive results.

In contrast, conformal cooling channels follow the shape of the form within the core, cavity and slides, thereby eliminating hot spots and achieving temperature uniformity in the plastic material being moulded. This results, not only in improved part quality, but reduced cycle times and therefore overall cost savings.

OPTIFLO® technology service makes conformal cooling affordable for our customers, delivering non-corrosive, fully hardened 52 HRC cores, cavities and inserts that are guaranteed for 1,000,000+ cycles.

This service allows supply of individual cores for your exiting tools as well as fitting into a new mould tool.

Why use conformal cooling?

Advanced thermal control

Conformal cooling channels closely follow the mould form to reach crucial hard to reach areas and can be used to create increased coolant flow to carry off more heat for uniform temperature control.

Improved dimensional control

Having the benefit of optimised thermal control in hand leads to increased part dimensional control, allow tighter tolerances to be achieved with parts off mould, reducing the need for mould progression after trials and time on optimising your moulding process.

Reduced cycle times

Optimised cooling throughout the mould reduces cooling time especially for problematic areas such as thick wall sections and lack of drafted forms.

Improved non-uniform shrinkage

Better mould temperature uniformity reduces differential shrinkage and therefore warping and shrinkage, leading to lower scrap rates and improved part quality.

Why choose us?

OPTIFLO® is delivered into the Plastics Industry in collaboration with our sister company in China, Cybertools Mold Tech (Dongguang) Co. Ltd. All elements are designed by our specialist design engineers in our UK and Chinese facilities, where they work together for the ultimate result. Their in-depth knowledge of the tooling and moulding process enhances their skills in thermal optimisation and Mould Flow Analysis software is used to test and hone the channels to maximise efficiency for optimum performance.

We have a long collaboration and experience with our chosen Chinese AM company who offer an extremely professional and technical service. Using the latest in AM machinery and 3D printable steels which replicate traditional moulded steels in moulds, has been proven to be significantly cost effective which also reduces internal cooling blockages and scale.

Maintaining and cleaning the channels result in faster cycle times due to a 27% increase in liquid flow.

Reduced Cycle Times

Reduced Cycle Times